What are the best ways to minimize cost overruns?

Large and mid-sized CAPEX & Infrastructure construction projects are many times, intricate and demanding. The majority of these projects significantly do not meet their pre-established cost & schedule goals.

What are the reasons for cost overruns on many construction projects? How can we minimize the cost overruns?

These are the questions I often get asked.

I have already covered in detail the top 20 reasons why so many construction projects overrun their budgets in another article. In this post, I will show you how to alleviate or minimize cost overruns.

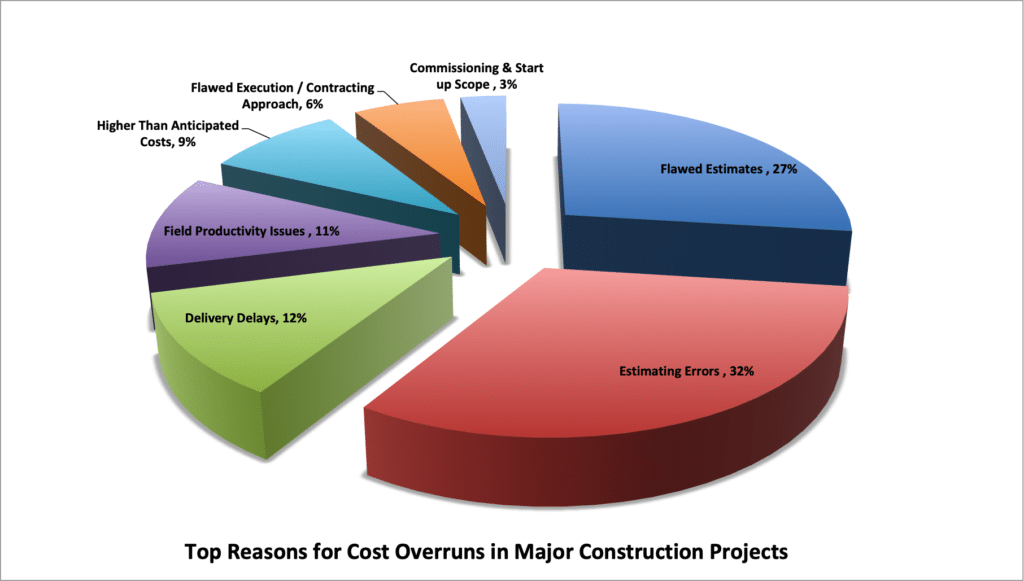

Cost Overrun Analysis

Over the last decade and specifically in the last 18 months, at Compass International, we have reviewed & analyzed over 20 major construction projects, which experienced cost overrun. The projects were from various industries, including Oil & Gas, Infrastructure, Pharmaceutical, and Commercial Buildings.The final construction cost on these projects exceeded the approved authorized budget by more than 15%, and in some specific cases, these cost overruns exceeded 75%.

Our research has determined the following major reasons of why these types of projects experience cost overruns.

- 27% of the cost overruns were caused by flawed estimates that were based on inadequate/incomplete scope definition or scope that was changing prior to and after the projects Final Investment Decision (FID) authorization.

- 32% were due to estimating errors related to quantities, bulk material prices, man-hours, and field indirect requirements.

- 12% delivery delays of major equipment, modules, and piping systems causing additional general conditions (preliminaries costs were the reason.)

- 11% field productivity issues (some of these projects did not consider, tight or overcrowded work areas, were the use of construction equipment was restricted& actual field performance).

- 9% was due to higher than anticipated labor, material, and indirect costs.

- 6% the execution/contracting approach was flawed.

- 3% the commissioning & start-up scope was not fully considered.

It is worth noting that more than one of these issues was encountered on some of the projects that were searched.

Our cost overrun analysis research did not consider construction-related “soft costs” such as pre-construction expenses, environmental and construction permits, Owner involvement (buy out of long-lead items & EPC oversite), state & country grants /incentives, tax holidays, future workforce training grants, FEED/front-end studies, offsite temporary storage, state tax exemption credits, attitude& ability of the Project Management team.

For example Project Management Team A may be much more knowledgeable, energetic, cost cognizant & schedule-driven than Project Management Team B or Team C, utilizing Project Management Team A can result in significant field construction cost savings, this is extremely hard to measure. However, experience indicates that this situation is a reality.

Cost Overrun Analysis – How to Minimize Cost Overruns?

Construction cost overruns are an everyday occurrence on mid-sized and large multi-million dollar EPC projects around the world.

As many as 6 out of 10 major construction projects fail to meet their established cost & schedule goals.

What can we do about it?

How can we minimize cost overruns?

I will endeavor to list out possible ways this situation can be corrected.

This article is focused/biased towards Industrial – Process CAPEX/EPC related projects valued up to one or more billion dollars, however it also is germane to Infrastructure type projects.

Conceptual/Front End estimates are many times underestimated in many cases due to inadequate or poor scope definition. Estimates that are based on preliminary scope and design basis should of course contain a higher percentage of contingency than estimates supported by more complete/solid design & scope deliverables.

For the last 35 years, I have been a Senior Construction Manager & Chief Estimator with both Owners & Contractors involved with 100’s of mid-sized & large EPC related Process, Industrial, Infrastructure & Pharmaceutical Projects in the USA & around the world. I have been involved with a lot of successes, however I have seen a number of failures on these types of projects.

I frequently get asked my opinion on this topic of cost overruns. Following is my observations & comments on this important topic.

I listed out the top 20 reasons (Part 1) why so many construction projects overrun their budgets. In this post (Part 2), I focus on how to minimize cost overrun issues in construction projects.

Clearly Define The Scope Of The Project

Sufficient time & resources must be allocated to defining the scope of the project.

The relevant team members must identify the project goals and objectives, function, operating systems, project phases, future EPC activities, schedule, and any constraints. All EPC work items must be listed out.

Work items that are overlooked or are ambiguously described, and ill-defined, will many times have a negative impact on the final estimated cost.

Scope growth during the initial stages of the project must be evaluated & included where possible in the cost estimate.

The resulting scope statement /report will be the road map for all team members on what is included in the scope of work and what is excluded from the future project.

Determine The Estimating Methods & Approach

The Estimating Team/Estimator(s) need to fully be familiar with the project’s scope of work to ensure no work is overlooked or missed in the CAPEX Cost Estimate. Many times too little time and resources for completion of the Estimating/Proposal effort is a major reason for cost overruns.

You need to determine the estimating methodology and communicate it clearly to the team. Here are some suggestions:

Conduct an Early Cost Estimating Kick-off Meeting

An early cost estimating and schedule kick-off meeting is crucial for all estimating/proposal team members. Estimate timing, roles, responsibilities, and estimate deliverables should be discussed & documented.

Develop an Estimating Plan

An Estimating Plan should be initiated following the kick off meeting.

The Estimate Plan outlines the information that the Estimating Team requires to complete the estimate. It should list out the individuals and the dates that information is required. Questions such as:

- Who provides the priced out major equipment list, plot plans, temporary site facilities, construction execution philosophy, site staffing needs, major milestone schedule indicating the start & finish dates of the civil, structural steel, process & utility piping,

- Who is responsible for obtaining prices on the major equipment,

- Who decides on which vendor quote to use in the estimate, the lowest cost or the mid cost range,

All of these questions need to be raised. Other design deliverables, sketches, and other key items that are needed should be requested.

On large complex projects the estimating effort could take 4 to 8 weeks to complete. The Estimate Plan should be updated each week and focuses on any delays or roadblocks that could jeopardize the estimate completion date.

Have a Clear Communication Plan

Communicate Estimators names, emails, and phone numbers to all team members. Select the Lead Estimator that all communications should be sent to.

Determine the Construction/Contracting Strategy

Decide estimate format, which WBS/COA will be utilized Owners or Contractors.

Where will the Material, Labor, Construction Equipment unit rates come from? Internal sources or sub-contractor pricing?

How will waste/over purchase of quantities be determined?

The Estimator needs to understand the construction/contracting approach, i.e. Union or Open Shop Labor, Direct Hire or Sub-Contractors.

The Estimator needs to ensure/compile an accurate quantity take-off of all the engineered & bulk material required for the project. If an independent engineering group or a third party provides some of these quantities, the Estimator needs to complete a spot check of some of these quantities to ensure the accuracy of the quantities.

Interact with the Procurement Team

The Estimator(s) need to interact with the Procurement Group to understand:

- What is the price of major equipment/production equipment

- What are the delivery issues,

- Who will set and align equipment,

- How was the freight determined,

- Are there any import duties,

- How is the cost of inspection/witness testing of major equipment determined,

- Should vendor assistance costs be included in the estimate,

- Should spare parts be part of the estimate.

Organize a Site Visit

The Estimator/Estimating team needs to visit the site to better understand the scope of work, review site logistic issues, and clarify the following:

- Are there any obstructions such as existing pipe racks/bridges that will get in the way with allowing major equipment deliveries, or heavy lift cranes to get onto site,

- Will demolition of existing facilities be required,

- Are any existing equipment items & piping systems to be re-used or relocated,

- Were will material/production equipment lay down areas be located,

- Is there a need for a temporary parking lot for the possible 500 to 1,500 construction workers,

- Will buses be needed to transport works onto the site & the location of existing utility tie in points,

- Is the process/utility piping to be fabricated at site.

- What are the local bulk material pricing, and local taxes,

- Are VAT rates applicable to materials, import duties,

- Will there be a need to produce/batch concrete at the site or purchase concrete from a vendor,

- Will a sizeable effort be needed to establish temporary roads onto the site, will these need to be maintained & eventually removed,

- What are the plant hire/construction equipment needs; field offices, temporary camp for the workforce, and offsite storage trailers

Maintaining sketches & locations of these assumptions are vital.

Maintain a Complete Cost Estimate File

It is essential that the lead Estimator maintain a complete “Cost Estimate” file that contains:

- memos,

- minutes of meetings,

- e-mails,

- quotations, l

- list of drawings,

- scopes of work,

- sketches,

- work breakdown structure,

- conference calls,

- important telephone conversations,

- scope revisions,

- photographs/videos & site visit reports.

It is very important to keep & make notes that will most probably be required later on in the projects life cycle.

Develop The Appropriate Unit Rates, Pricing, And Labor Productivity

An inconsistent cost estimate that is based on inaccurate quantities, bulk material unit costs, labor rates, major equipment costs, construction equipment/in-directs & labor productivity expectations can have a serious cost impact on the final cost estimate. This in turn can lead to an unreliable schedule & increase the risk of an estimate overrun.

Is the project in an overseas country, labor productivity may be different in “tight” work areas were construction equipment use is limited vs.open field areas.

The Estimator(s) of course must develop the appropriate bulk and engineered material unit prices, major equipment prices & installation values, man-hour production rates, wage rates & in-directs.

Labor productivity value for each craft /work area needs to be estimated, productivity will vary from congested/tight/restricted work areas from open areas.

Develop The Basis of Estimate (BoE)

The basis of estimate needs to be a comprehensive listing of all the estimating assumptions and exclusions;

- what is included and excluded from the estimate,

- what Provisional Sums, allowance & assumptions have been made in the CAPEX Cost Estimate, (including the list of drawings & revisions that the CAPEX Cost Estimate is based upon).

The estimate basis should describe in detail, the engineering deliverables/ drawings, c/w drawing #’s, revisions, sketches, (SOW) documents, inclusions, assumptions, exclusions & estimating assumptions, currency exchange rates, US & International inflation rates that were utilized, and import duties/taxes that the estimate is based on.

Validate the CAPEX Cost Estimate

The Estimator(s) must validate if the CAPEX (Capital Expenditure) estimate is in concurrence with the established project scope.

An In depth QA/QC review needs to be implemented by the estimating/proposal team prior to estimate finalization to ensure the correct labor costs, man-hours & productivity targets have been appropriately estimated.

Here are some suggestions to consider in the review of CAPEX Cost Estimates:

- A number of work activities such as startup or shutdowns may possibly need to be completed using shift work, weekend work or on overtime.Make sure this cost is captured in the CAPEX cost estimate.

- Field In directs/Preliminaries or General Conditions as it may time referred to should be itemized in the estimate. Many times a percentage of direct field labor is used. This method is not accurate. The estimating team should list & price out field supervision, fringes/burdens, site establishment/temporary facilities, small tools, scaffolding, construction equipment, heavy lift cranes, clean up, field expenses & the like.

- If the project is located overseas, the CAPEX Cost Estimate should include a statement/language of what the currency exchange rates were on the particular date the estimate was compiled or what the exchange rates were on specific items of major equipment (for example the major equipment could be coming from numerous European & Asian suppliers).

- Check whether there is language in the CAPEX Cost estimate basis that spells out the assumptions made on severe weather conditions when compiling the estimate.

- All provisional sums & cost allowances should be fully described & priced out. Check whether the Consequential/Liquidated damages & penalty clauses have been addressed & priced out in the CAPEX Cost Estimate?

- Shortage of skilled site construction workers is another point to consider. For example does the contractor has to hire pipefitters from 100 – 500 miles away? Has this travel/lodging cost been accounted for in the CAPEX Cost Estimate?

- The need for hot work permits in an existing operating facility & the time lost by specific work crews waiting for the required signed off documentation needs to be estimated & described.

- Contractual Terms & Conditions on issues such as Owner Provided Equipment c/w with delivery dates at site, Owner Provided Insurance (OPI), BAR Insurances, Performance Bonds, Payment timing (i.e. 45 – 90 days before payment), Extended Warrantee issues, Substantial completion definition, Scope changes, Performance Guarantees, Parent Company Guarantees, Retention funds and the like. The cost of these items needs to be established and be made part of the CAPEX Cost Estimate.

Adequate time must be assigned to a detailed review of the final estimate, ensuring the estimated cost values align with the (SOW) descriptions.

Determine totality of the CAPEX estimate & make certain that there is no omitted scope of work or discrepancies.

A benchmark evaluation comparing the estimate with historical values will be beneficial in conditioning the final estimated cost to ensure all scope items have been captured. Many times the cost estimate is compiled with an attitude of arriving at the lowest cost, this can sometimes be detrimental to the final estimated cost. Senior management typically makes the final decision on overhead costs, engineering man-hours & costs, contingency, management reserve, warranty guarantees& profit margins after they have been fully briefed by the estimating team.

Many construction related organizations (Owners & Contractors) do not provide adequate support (estimate budget, manpower, estimating department overtime & travel costs to site) during the estimating effort. This coupled with Senior Managements predictable predisposition in reducing engineering hours, allowances, contingencies, overhead & profit margins in their quest to ensure the project moves ahead. These issues together with not spending an adequate amount of time in fully understanding the overall scope, project risks&conferring in detail with the Estimator(s) on these important issues is another cause for cost overruns.

The CAPEX cost estimate should be accepted by all the project team members. This calls for a rigorous interaction & agreement with the Owner, EPC Company, Design Team, Project Management, Procurement, Project Controls (Estimating) & Construction Team.

Investigate, Research, & Document Escalation/inflation/currency Exchange Rate Estimates

Frequently CAPEX estimates are compiled utilizing the most optimistic escalation rates. Major projects that are in the field for 2, 3 or 4 years are particularly vulnerable to increased costs related to labor, bulk & engineered materials & field in-direct costs.

The correct path forward is to investigate, research & document various escalation/inflation index &indices such as Government agencies publications, Wall Street Journal, World Bank publications on projected escalation & currency exchange rates.

State what the basis of escalation & exchange rates were at the time the cost estimate was produced. Increases of 2% or 3% each year over say a 3-year execution period can equate to a sizeable component in the estimate.

Currency fluctuations is another issue that needs to be addressed, just consider the currencies of the UK, Turkey & Mexico in the last two years, the exchange rates that were utilized in compiling the estimate needs to be stated in the basis of estimate (BOE).

Reflect The Planned EPC Strategy In The Cost Estimate

Lack of a detailed Engineering, Procurement Construction (EPC) & handover execution plan many times will result in cost overruns;

- Is the project going to be stick built or modularized?

- Is the field labor cost based on Union or Open Shop labor?

- Can the field in-directs be reduced if a higher percentage of modularization is utilized?

The estimated cost needs to reflect the planned EPC approach & strategy. There is an assortment of project delivery possibilities available to construct a facility. Selecting the appropriate delivery method is important and can have cost ramifications.

Some of the more frequently used methods are:

- Turnkey,

- Engineering, Procurement & Construction (EPC),

- Design Build (DB),

- Target Price with shared savings,

- Construction Management & Guaranteed Maximum Price.

Issues to consider in the selection criteria are cost, schedule & contractor capability & risk reduction.

“Front End Planning” is the critical activity that Project Managers/Project Controls professionals need to consider in minimizing cost estimating overruns and schedule delays. The more time and resources that can be allocated to this effort usually pays off in minimizing future cost & schedule issues.

Review Early Estimates/Feed Studies/Conceptual Estimates

Early/Front End cost estimates many times have a tendency to contain errors such as, missing scope, understated quantiles, inaccuracies in determining wage rates, bulk material unit price oversights, and establishing the field force labor productivity rates.

Another area that can cause overruns is underestimating the field in-directs. On some occasions these Early/Front End cost estimates are completed by individuals or teams that have a vested interest in the future project moving forward. This bias can seriously impact the estimated cost.

The only way of dealing with this situation is for an independent expert to review the estimate or for the Estimator/Estimating team to painstakingly review & check the details of the latest estimate to ensure this situation is rectified.

Conduct Early Front End Planning

Early team planning sessions is the key to success on any major industrial project. These meetings can mitigate possible future cost & schedule problems.

Having a team planning session/estimate – schedule kick-off meeting allows the Estimating/Proposal team to layout issues, timing, roadblocks and possible solutions to meet the estimate due date.

Base The “Baseline” Estimate On A Documented List Of Drawing And Specifications

The Estimator/Estimating team must endeavor to base the estimate on the original scope document. Dealing with scope changes is one of the leading issues the Estimator/Estimating team has to contend with.

What would seem to be a minor change to a major piece of equipment can have serious consequence to foundations, piping systems, and insulation to mention just a few. The only way to deal with this is to base the estimate on a documented list of drawings & specifications.

Scope modification/design changes can significantly impact early received quotes related to major equipment & engineered materials (i.e. tagged items). Engineering/sizing changes to major equipment many times increases the cost of major equipment items & increases the flow rates, pumps & piping sizes. Some design changes are inevitable. The only way to deal with this is to base the “baseline” estimate on a documented list of drawings & specifications and include these comments in the (BOE).

Develop Realistic Schedules

A vigorous independent in-depth review of the schedule utilizing experienced planning professionals is required to ensure the schedule is not over optimistic. If the estimate is incorrect then there is a high probability that the schedule will be wrong. The schedule should carry enough “float “to allow for late major equipment delivery, accidents, re-work, field change orders & possible extreme weather.

Consider Risk Management Systems

Every construction project has challenges & associated risks.

The estimating/tender team &individual’s familiar with “Risk Management” are required to list out specific technical & commercial risk related possibilities& situations that could arise on the future project. When the technical & commercial risks have been identified the risks can be scoped out and evaluated, priced out, and where appropriate included within the estimate.

Utilize Experienced Project & Construction Management

Inexperienced Project Managers that lack critical know-how and the self-confidence to lead the project team can be a serious problem that can lead to cost overruns.

A high percentage of major projects and their budgets (estimates) get into trouble because inexperienced/unproven Project & Construction Managers are managing the EPC effort.

To successfully execute the multimillion-dollar major complex industrial projects, the Project & Construction Managers should have at least 10 years direct experience in managing, estimating, procuring, scheduling & controlling these types of projects. Owners/Operators many times make the fatal mistake of choosing “MBA/Financial” type individuals, with little or no knowledge of EPC activities to look after their interests. The disturbing fact is that these individual don’t have the knowledge or experience to recognize (A) cost overruns, (B) schedule delays, (C) productivity trends and other issues that add costs to the project and cause delays that lead to extending the field in-directs.

Define Project Organization/Roles & responsibility

Projects that lack an organization structure many times lead to internal personnel disputes and poor interactions.

To be successful, individuals need to understand their roles & responsibilities. Basic manpower loaded schedules are needed to be established, indicating start & finish dates that the Project/Construction team will be mobilized & de-mobilized from the project. Failure to produce these documents can lead to individuals being on the project longer than required, resulting in potential cost overruns.

Another issue is that new Engineering/Construction Management employees are not given initial on boarding information on project issues/procedures that leads to these individuals spinning their wheels for the first 2 or 4 weeks of their assignment.

Perform Cost Control

Project cost control entails evaluating and accumulating actual material, labor, quantities installed to date, in-direct cost data, and forecasting the final cost of a specific line item being analyzed.

On many construction projects no real proactive cost engineering/project – cost control is performed. The cost control many times is an “accounting” effort, compiled after the work has been completed.

Lack of project controls/cost controls tools & procedures, together with limited proactive follow up to schedule slippage and low field productivity will many times set the stage for cost overruns.

The final detailed cost estimate contains the material, labor and in-directs data for controlling project costs. To minimize the cost overruns, the Project Controls team needs to be proactive and involved with all project related activities, advising the Project Manager on man-hour trends & budget variances so that mid-course corrections can occur.

Determine Correct Contingency Value/Estimate Accuracy

Historically a large number of construction projects have utilized between 5%-10% of the projects bottom line construction cost to establish the contingency value, which is the wrong approach.

Sufficient time must be assigned to determining the correct contingency value. This estimate component can be a sizable value of possibly more than 10% of the projects final cost.

The Estimator(s) need to be cognizant of the conceivable risks and challenges the construction effort will encounter and apply the acceptable contingency/management reserve fund that hopefully mitigates these issue.

Unrealistic & inadequate contingency/management reserve funds contained in the final approved project estimate can lead to estimate overruns. A detailed Monte Carlo/Range Estimating evaluation or a planned contingency session should be initiated towards the completion of the final cost estimate to determine the appropriate value.

Select The Best Construction Management Team

Selecting the “best” Construction Management team is the number one solution for successfully managing the construction effort. The key factors to consider are the skills, resourcefulness and abilities of the Construction Management team.

Construction Management Team A may be much more knowledgeable, energetic, cost cognizant & schedule driven than Construction Management Team B or Team C. Utilizing Construction Management Team A can result in saving significant field construction costs.

Safety, quality control, cost control,communications & physical progress are the key issues that need to be achieved during the construction effort.

Communicate, Communicate, Communicate

Project communications need to be clear, concise, and unequivocal.Otherwise, disorder and possible schedule slippages will occur.

Communications between all of the EPC team members, including the construction field force on the project is essential to meet major milestones and budget targets.

Good communications is essential to the successful handover of all construction projects. Flawed communications will many times lead to conflicts, delays in misunderstandings, delays & possible change orders.

Develop Clear Specifications/EPC Procedures

Complex specifications, EPC procedures and reporting systems such as RACI matrix type tools and the like that are many times not fully understood or correctly utilized by the EPC team can lead to man-hour & budget overruns. Many of these systems do not add value to the project and can indirectly result in cost overruns.

As we move into the future, latest technology such as Building Information Modelling (BIM) 3D model-based procedures provide tools to cost-effectively map out, engineer, procure, and construct various facilities.

Developing standardized specifications is another area were resources & costs can be optimized.

Improve Construction Productivity

Low labor productivity is a significant cause for cost overruns on construction projects. Construction productivity can be improved by utilizing more offsite or onsite pre-fabrication methods such as pre-cast concrete, piping systems, modules, and pre-assemblies.

To maximize worker productivity – Issues such as busing the workers to their work area each morning, bulk materials & construction equipment, should be readily available close to the work area, toilets & change rooms should be clean & close to the field force, keeping the field force appraised of the projects status.

Other issues that can impact productivity and costs are high field labor turnover & poor field supervision. Issues that negatively impact productivity are deficient material logistics, periods of extended overtime, restricted & congested work areas/space, worker turnover/nonattendance, wrong crew size, lack of correct construction equipment&hazardous or restrict work areas.

If these issues can be resolved then construction productivity can be improved, which subsequently minimize cost overruns.

Review and Assess Contractual Terms And Conditions

Contractual Terms & Conditions on issues such as

- Owner Provided Equipment c/w with delivery dates at site,

- Owner Provided Insurance (OPI),

- BAR Insurances,

- Performance Bonds,

- Payment timing (i.e. 45 – 90 days before payment),

- Extended Warrantee issues,

- Substantial completion definition,

- Scope changes,

- Performance Guarantees,

- Parent Company Guarantees,

- Retention funds

The cost of these items needs to be established and be made part of the CAPEX Cost Estimate. In addition, if the contract calls for Consequential/Liquidated damages and penalty clauses, these requirements/issues need to be addressed in the CAPEX Cost Estimate.

Confrontational contracts and contracting methods that are ill-defined and lack a detailed unit prices/labor – construction equipment rates/schedule of rates for change orders can lead to disputes & cost overruns.

Evaluate and Price Out The Commissioning/Start Up Costs

The commissioning &startup activities can be characterized as the interim step between facility completion (construction) and the facility operations/production life cycle (operations).

Commissioning & Start up includes such items as hydro & pressure testing, systems checking &plant turnover, and equipment performance/witness test examinations.

Commissioning & start up activities also includes leak tests on flanges, fittings, connections,gaskets, welds, valves, acid washing/passivation activities, if required.

To minimize cost overruns later in the project, these activities need to be evaluated & be price out & included in the CAPEX cost estimate.

Coordinate Field Mobilization

Field mobilization, i.e. going onto the construction site & establishing the temporary construction facilities & operations required for the construction of a project is an important milestone that needs to be carefully coordinated with major equipment deliveries & the need to construct various foundations & incoming unities.

General Condition’s/Preliminaries (field staff, trailers, construction equipment) durations & potential cost overruns can occur if the mobilization effort is not carefully scheduled& the field staff is at the construction site 2 or 3 months before they are required.

In Summary:

Construction cost overruns and schedule delays are a common place occurrence on many mid-sized & large multi-million dollar EPC projects around the world. More than 60% of these projects fail to meet their pre-established Cost and Schedule goals.

Based on the above research of completed mid-sized and large multi-million dollar EPC projects, in an effort to minimize cost overruns, below is the suggested list of important actions that need to be considered:

- Clearly define the scope of the project

- Determine the estimating methods & approach

- Investigate, research, & document escalation/inflation/currency exchange rate estimates

- Reflect the planned EPC strategy in the cost estimate

- Review early estimates/feed studies/conceptual estimates

- Conduct early front end planning

- Base the “baseline” estimate on a documented list of drawing and specifications

- Develop realistic schedules

- Consider risk management systems

- Utilize experienced project & construction management

- Define project organization/roles &responsibility

- Perform cost controls

- Determine correct contingency value/estimate accuracy

- Select the best construction management team

- Develop clear specifications / EPC procedures

- Improve construction productivity

- Review and assess contractual terms and conditions

- Evaluate and price out the commissioning/start up costs

- Coordinate field mobilization

- Communicate, communicate, communicate

I invite your feedback & comments on this interesting subject.

About the Author, John G McConville CCP

John is the Operations Director of Compass International, a Cost Estimating/Procurement Consulting & Publishing firm, which is known around the world as “the experts” on US & International Construction Costs, Global EPC Procurement & Construction Productivity.

John has over thirty years’ of experience related to Cost Estimating, Estimating Reviews / Validation Services, Turnaround of Problem Projects, Independent Estimates for Owners & Value Engineering on a wide variety of major EPC projects, including: Petro-Chemicals, Manufacturing, Industrial Gases, LNG, Ethylene, Pharmaceuticals, Pipelines & Offshore Facilities located in more than 25 countries.

John’s three decades of executing & researching major Industrial, Infrastructure & Commercial projects at Compass International, Mobil Oil, Bristol-Myers Squibb & Linde Gas has been the foundation of this expertise. He has analysed the many issues that influence EPC projects in succeeding or failing to meet their stated cost & schedule goals.

John is the Author of 9 important books on US/International Construction Cost & International Procurement Practices, He has presented more than 100 Conceptual – Detailed Estimating, Project Management & Value Improvement training programs to 3,000 + Construction Professionals from Government Agencies, Universities, Fortune 500 companies & EPC firms in USA, Canada, Venezuela, Norway, Netherlands, India, UK, Saudi Arabia & Malaysia.

John is a Certified Cost Professional (CCP) with the Association for the Advancement of Cost Engineering (AACEI).

Connect with John via LinkedIn or his website.

![[Free 90-min Masterclass] The Ultimate Leadership Recipe for Project Professionals](https://www.projectcontrolacademy.com/wp-content/uploads/2024/08/4-1024x576.jpg)