Schedule Delays in projects are a harsh reality. With so many uncertainties, you are almost always bound to face delays for one reason or another in projects.

When delays happen, schedule delay analysts bear the burden of selecting the appropriate schedule delay analysis methodology to analyze and quantify schedule delays, and concurrent delay.

However, selecting the most adequate schedule delay analysis methodology remains a subject of controversy.

That’s why I wrote this blog post to walk you through the different schedule delay analysis methodologies outlined in AACE RP 29R-03, Forensic Schedule Analysis Recommended Practice, and highlight the advantages and disadvantages of these methods, their sources validation protocols and try to establish a practical method to choose the adequate Method Implementation Protocol (MIP).

Let’s explore how and why to select a schedule delay analysis methodology below!

Understanding the Challenges in Assessing Schedule Delays

You are not alone in dealing with the schedule delays. Schedule delays often occur in projects, resulting in delay claims and disputes, and ultimately in severing relationships between project stakeholders.

Industry publications demonstrate multiple methodologies to analyze and quantify project delays. However, these methodologies have different analytical approaches and therefore yield different results [1]. In addition, each claim is unique in that each claim deals with a different project, different contract documents, different legal jurisdictions, different dispute resolution mechanisms, etc.

Selecting the appropriate schedule delay analysis methodology depends on multiple factors, including the contractual requirements, data availability, time of analysis and capabilities of the method, as well as time, funds and effort allocated to the analysis [1] [2] [3].

Determining the appropriate method can also depend on the size and complexity of the dispute, the purpose of analysis and targeted accuracy, the forum of resolution and audience, legal and procedural requirements, stability of sequence and construction methodology and complexity of project baseline and updates, among others.

Consequently, the choice of the adequate schedule delay analysis methodology to quantify delays stays in the hands of the forensic delay analyst, who will leverage his/her knowledge of the listed factors above, to select the right method.

Now that we understand the challenge, what methodologies exist in the industry? And what are the advantages and disadvantages of these methods?

Schedule Delay Analysis Definitions & Terminologies

Before delving into the discussion, let us define a few concepts that I will repeatedly reference in this blog post:

Critical vs. Non-critical Work

Critical Work is a certain work that must be completed at any given point in time so that the completion of the project does not slip to a later time. When your project is scheduled using the CPM scheduling method, the critical work is identified as the work on the “longest path” or “critical path.”

Non-critical work can be delayed a certain amount of time without affecting the completion of the project. Such an amount of time is defined as “total float” or “total slack.”

As-planned vs. As-Built

As-planned network is the network of activities that represent the manner in which the project is planned to be executed.

As-built network is the network of activities that represents the manner in which the project was built.

Retrospective Analysis

Retrospective analysis or forensic delay analysis is an after-the-fact analysis of a delay event after it occurred, providing the advantage of hindsight on the project as-built information [4].

Static vs. Dynamic Analysis

Static delay analysis is a delay analysis method that focuses the measurement of performance against a single as-planned network.

Dynamic delay analysis is a delay analysis method that involves measuring performance by use of approved schedule versions (i.e., schedule updates).

Forensic Schedule Delay Analysis Methodology Implementation Protocols (MIP)

Prior to adopting the method implementation protocols for the different forensic schedule delay analysis methodologies, you need to ensure the reliability of the source data that will be used for your analysis [4].

The accuracy of the result of any schedule delay analysis methodology implementation will heavily rely on the validity and reliability of the analyst’s source of data, including contemporaneous project documents, data, and witness statements [4]. As such, the source validation protocols must include the following steps:

- Baseline Schedule Selection, Validation, and Rectification

- As-Built Schedule Sources, Reconstruction, and Validation

- Schedule Updates Validation, Rectification, and Reconstruction

- Identification and Quantification of Discrete Impact Events and Issues

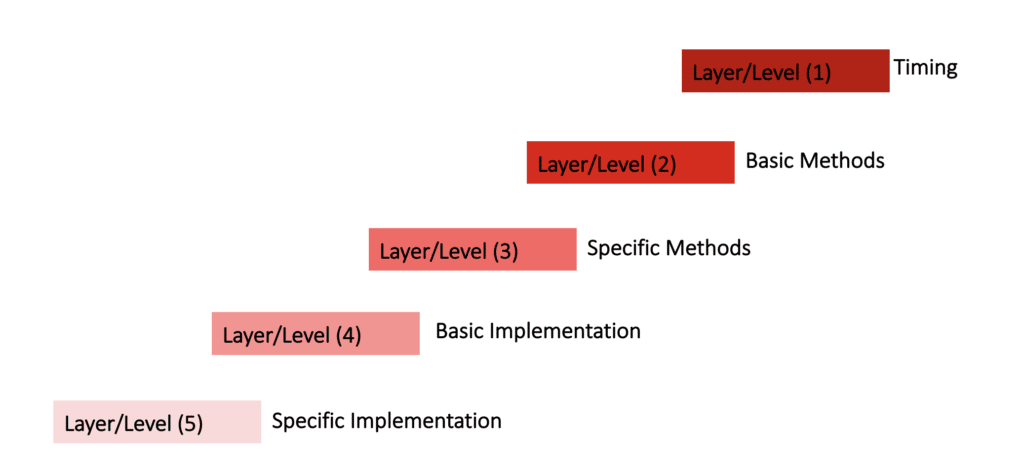

After understanding the source validation protocols above, let us discuss the method implementation protocols described in RP 29R-03. Fig. 1 below describes the layers and levels of the RFP 29R-03 MIPs.

Figure 1: Schedule Delay Analysis Methodology Implementation Protocols Layers/Levels (RP 29R-03).

Going from the top to the bottom, Fig. 1 demonstrates how the MIPs are organized, starting from the first layer; timing of delays (i.e., prospective vs. retrospective), then the second layer; the basic methods identifying whether the delays are analyzed observationally or in a modeled manner. The third layer differentiates between static, dynamic, additive, and subtractive methods. The fourth and fifth layers delve into further detail on how you can implement these methods.

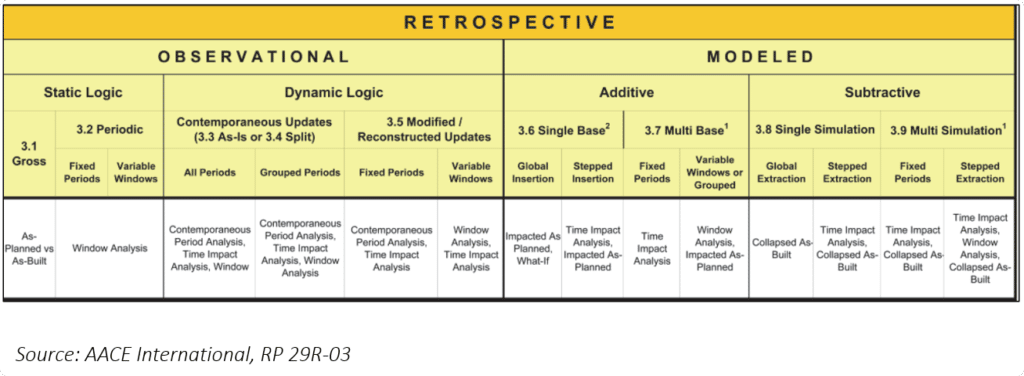

Fig. 2 below represents the RR 29R-03 Taxonomy Table that outlines the different forensic schedule analysis methods.

Figure 2: RP 29R-03 Taxonomy Table- Schedule Delay Analysis Methodologies

But what is the difference between these schedule delay analysis methodologies, you may ask? Let’s explore below!

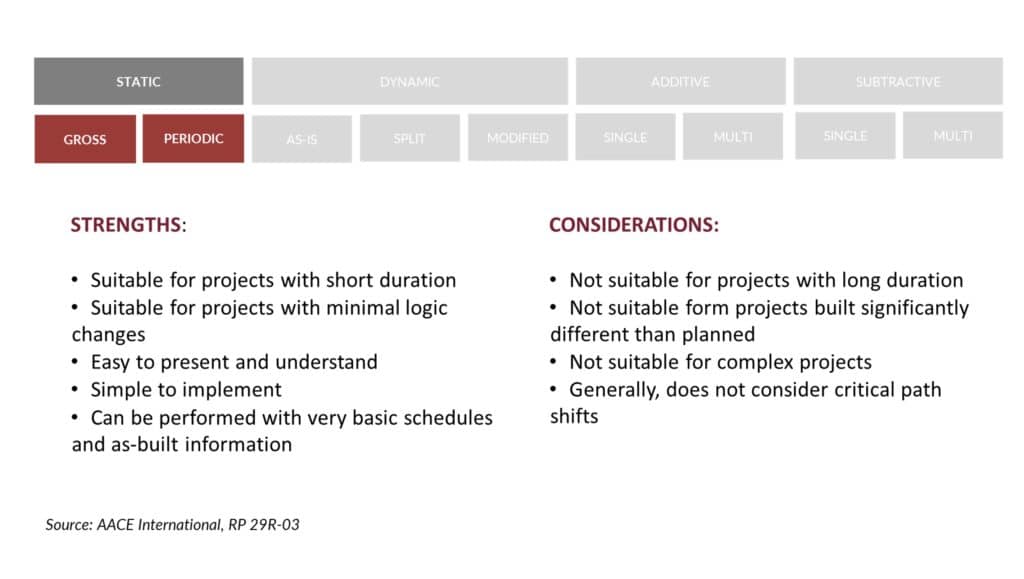

Observational Schedule Delay Analysis Methodology- Static Logic

Static schedule delay analysis methodology focusses on a single as-planned network [4].

The summary as-planned v. as-built method is one of the most used static methods to analyze and quantify delays for simple projects with a short performance period.

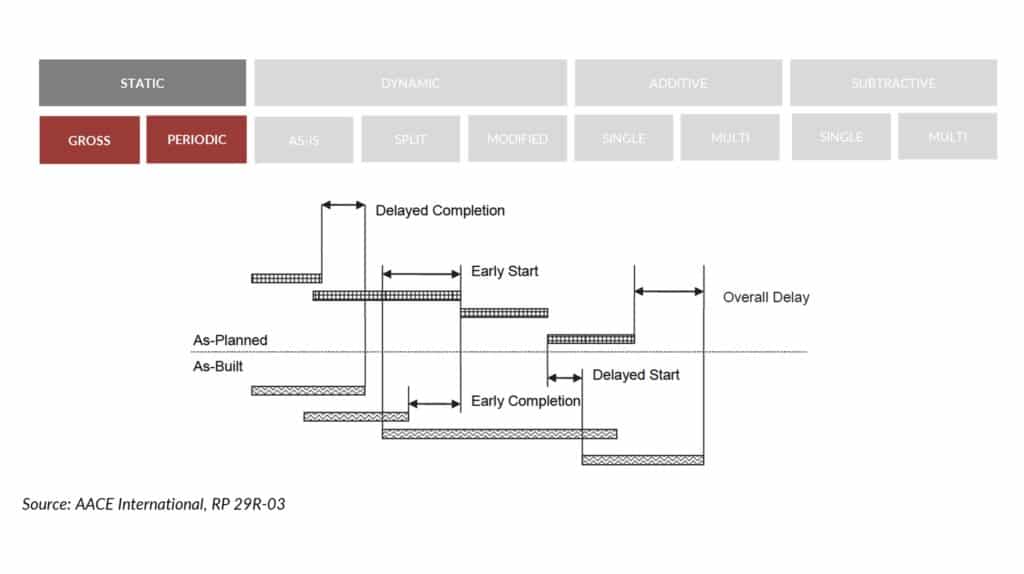

Fig. 3 below represents a visual illustration of the as-planned vs. as-built method.

Figure 3: As-planned vs As-built Method- Static Logic [1]

While easy to present and understand, simple to implement, and can be performed with basic schedules and as-built information, static methods assume that the project critical path does not change during the project and that contractors are required to follow the baseline schedule in terms of manpower mobilization, equipment mobilization, cash payments and sequencing among other logistical items, regardless of any changes incurred during the performance period.

As such, American courts and industry professionals have considered these methods to not be suitable for complex projects, with a lengthy period of performance, or for projects that are built significantly differently than planned.

Figure 4: Static Logic Schedule Delay Analysis Methodology- Pros & Cons

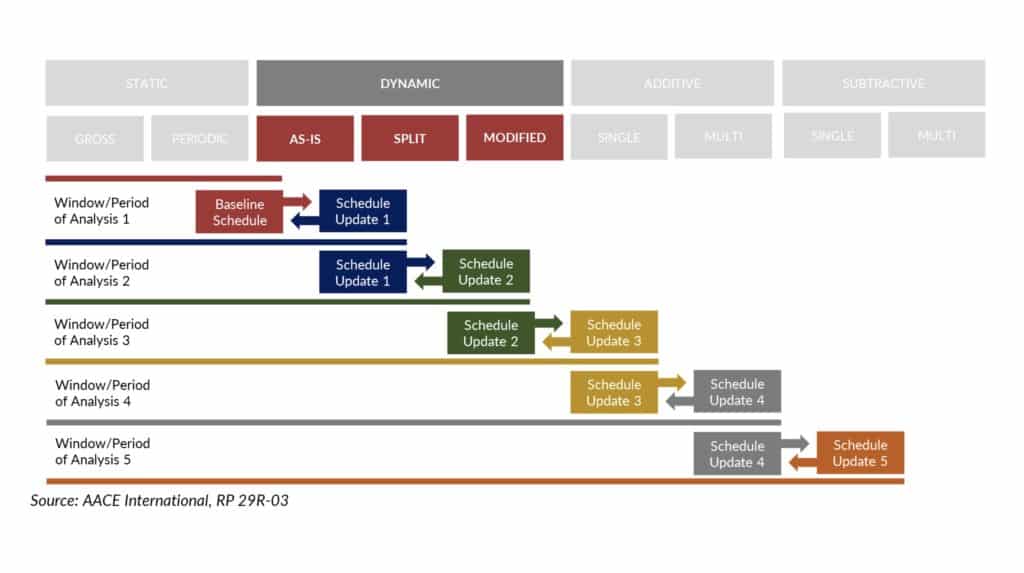

Observational Schedule Delay Analysis Methodology- Dynamic Logic

Dynamic schedule delay analysis methodology, comprised of “As-is,” “Split,” and “Modified” methods, involve using CPM (critical path method) schedule updates [4].

Observational analysis MIP 3.3 and 3.4 (windows) are two of the most recognized methods to analyze and measure schedule delays on complex projects with long performance periods [4].

Fig. 5 below represents a visual illustration of the As-is, Split, and Modified methods.

Figure 5: As-is, Split, and Modified Methods- Dynamic Logic Schedule Delay Analysis Methodology

Simply described, these methods divide the project period of performance into multiple windows (also called “periods”) to analyze the project delays within each period.

Therefore, these methods take into consideration the dynamic nature of the project critical path that is the result of the contractor adjusting its means and methods in terms of workforce, equipment utilization, cash flow, sequencing, and other logistical items as it encounters changes during the performance of a project within its update schedules.

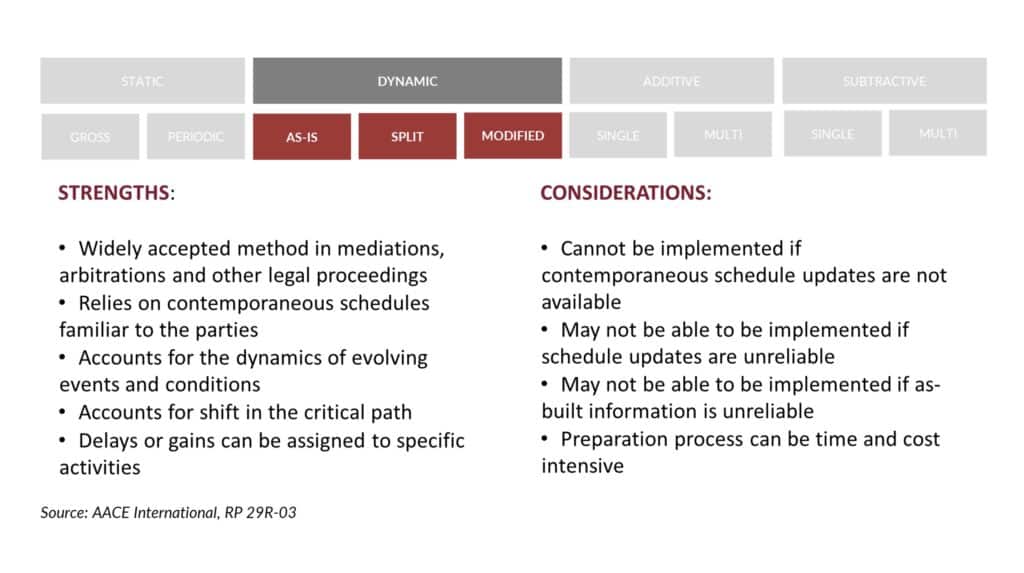

American courts and industry professionals have recommended the use of dynamic methods, as opposed to static methods, in that dynamic methods consider all scheduling information familiar to the parties, recognize the contractor’s duty and right to control its own means and methods (in terms of manpower planning, equipment planning, re-sequencing and other logistical items), accounts for the dynamics of evolving events and conditions, considers all changes to the project critical path which yield stronger causation linkage to delays or gains [2] [5] [6].

Though dynamic methods are the most widely accepted methods in mediations, arbitrations, and other legal proceedings, these methods cannot be implemented if contemporaneous schedule updates are not available or not dependable, and if as-built information is unreliable.

In addition, the method preparation and implementation process tend to be time-intensive and cost-intensive.

Figure 6: Dynamic Logic Schedule Delay Analysis Methodology- Pros & Cons

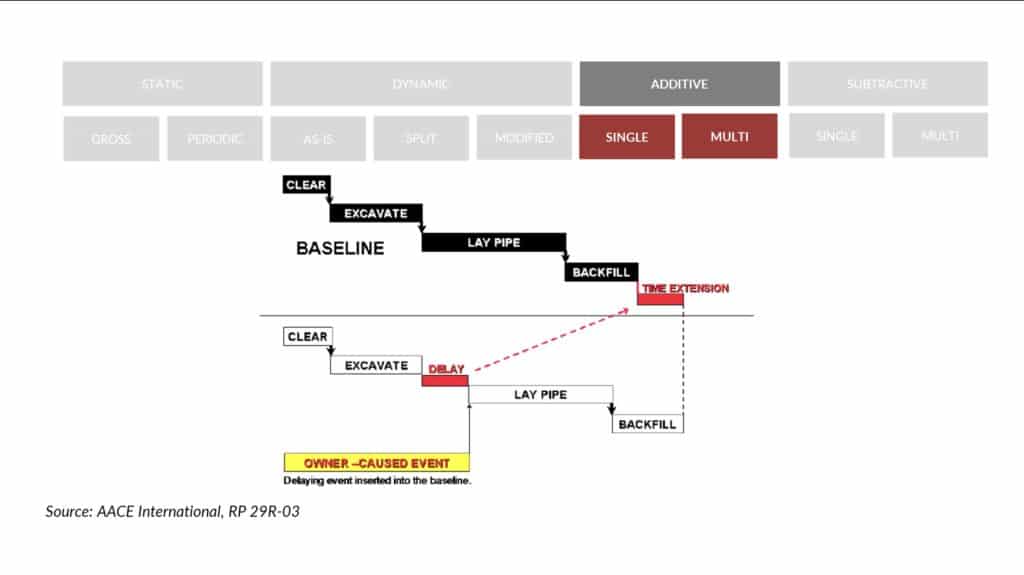

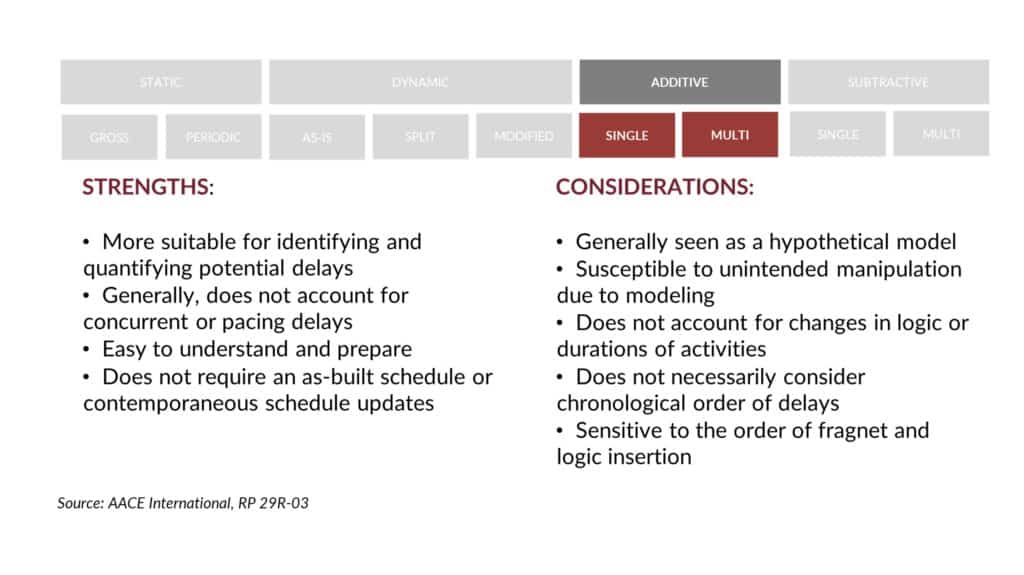

Modeled Schedule Delay Analysis Methodology- Additive Logic

Additive schedule delay analysis methodology consists of adding activities or fragnet(s) representing delay events to the project as-planned network(s).

You can add the delay fragnet(s) to a single project as-planned network or baseline schedule (i.e., MIP 3.6) or to multiple as-planned networks as delineated in MIP 3.7.

Fig. 7 below is a visual illustration of the additive delay methods.

Figure 7: Additive Logic Schedule Delay Analysis Methodology

Additive Methods are more suitable for identifying and quantifying potential delays (see RP 52R-06), are easy to understand and do not require an as-built schedule or contemporaneous schedule updates, depending on the MIP used.

However, these methods are seen as hypothetical models, can be susceptible to unintended manipulation due to modeling and do not account for changes in logic or activity durations.

Additive methods tend to be sensitive to the order of fragnet and logic insertion and do not appropriately account for concurrent or pacing delays. In these situations, a prudent strategy is to use enhanced implementation protocols outlined by RP 29R-03 or combine two methods or more to address an MIP shortcoming.

For example, if pacing or concurrency are occurring on a project, I advise analysts to use enhanced protocols or combine an observational method (e.g., MIP 3.3) with a modeled method, if modeling delays are a contractual requirement.

Figure 8- Additive Logic Schedule Delay Analysis Methodology Pros & Cons

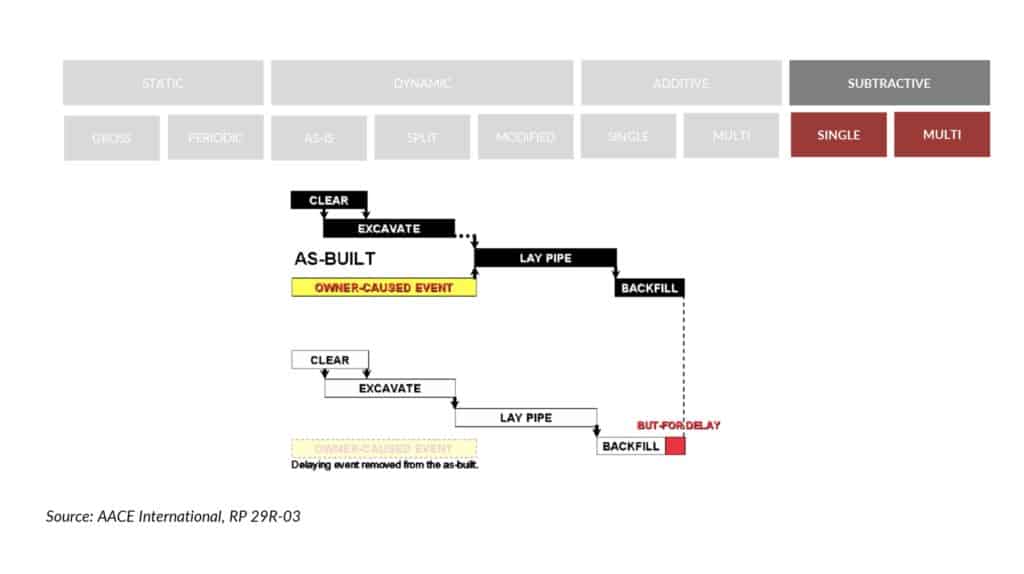

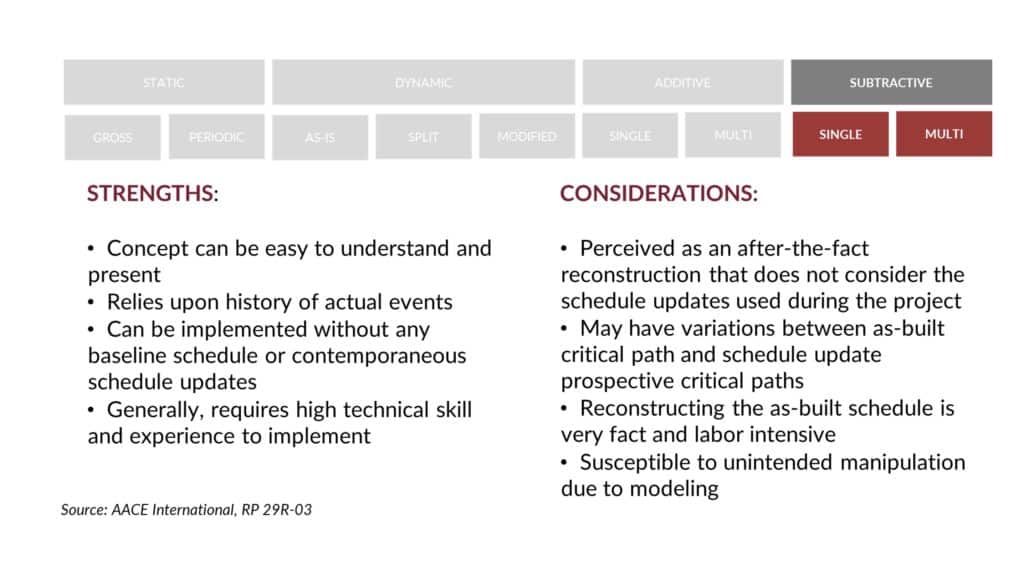

Modeled Schedule Delay Analysis Methodology- Subtractive Logic

While additive methods consist of adding delay activities to as-planned networks, subtractive delay analysis methods consist of subtracting activities or fragnets that represent delay events from an as-built network(s).

Fig. 9 below represents an illustration of subtractive methods.

Figure 9: Subtractive Logic Schedule Delay Analysis Methodology

Also called “But-for” analyses, subtractive methods tend to be easy to understand. These methods rely on the history of actual events and can be implemented by the forensic delay analyst without any baseline schedule or contemporaneous schedule updates.

However, subtractive methods are perceived as an after-the-fact reconstruction that does not require schedule updates used during the project and is familiar to all parties.

In addition, projects may have variations between the as-built critical path and the schedule updates prospective critical path which could impact the analysis results.

Reconstructing the as-built schedule is also very fact-intensive and labor-intensive, and the entire exercise can be susceptible to unintended manipulation due to modeling. Therefore, these methods require high technical skills and experience to implement.

Fig. 10- Subtractive Logic Schedule Delay Analysis Methodology Pros & Cons

Summary

Schedule delays are a common issue within the construction industry that often result in claims and litigation. Each claim is unique in that each claim deals with a different project, different contract documents, different legal jurisdictions, different dispute resolution mechanisms, etc.

Hence, multiple methodologies have been developed to analyze and quantify project delays. The choice of the adequate schedule analysis method depends on data availability, contractual requirements, time of the analysis, costs and level of effort, among other factors.

While static methods can arguably be used when you are working on a simple project with a short project performance and a minimal number of changes to the plan, American courts and industry experts have still favored dynamic methods in that these methods have historically been the most defendable and reliable methodologies for projects of significant periods of performance as such methods account for the dynamic and shifting nature of the critical path.

Now that we have reviewed the different schedule delay analysis methods, which method would you select for your project?

Whichever method you choose, wouldn’t it be great if you could have an expert opinion to assess your decision? Here’s some great news, you can!

Our Forensic Schedule Delay Analysis training is a comprehensive course fully aligned with the AACE Forensic Schedule Analysis Recommended Practice. What’s more, the course is developed and instructed by one of its primary authors, Chris Carson.

You have already invested your time and obtained great information out of this blog post. Now you have the choice to take great action, to consolidate and expand that knowledge in structured sessions. And we can’t wait to see you there!

References

[1] A. A. Bubshait and M. J. Cunningham, “Comparison of Delay Analysis Methodologies,” Journal of Construction Engineering and Management, Vols. vol. 124, no. 4, pp. pp. 315-22, 1998.

[2] D. A. &. T. Pattanakitchamroon, “Selecting a Delay Analysis Method in Resolving Construction Claims,” International Journal of Project Management, Vols. vol. 24, no. 2, pp. pp. 145-155, 2006.

[3] J. Yang and C. Kao, “Review of Delay Analysis Methods: A Process-Based Comparison,” the Open Construction and Building Technology Journal, vol. Vol 3, pp. pp 81-89, 2009.

[4] AACE International, Recommended Practice No. 29R-03, Forensic Schedule Analysis, Morgantown, WV: AACE International, Latest revision.

[5] B. B. a. M. Callahan, “Construction Delay Claims,” Aspen Publishers, no. 4th ed., 2011.

[6] T. D. S. H. a. M. G. J. Wickwire, Construction Scheduling: Preparation, Liability, and Claims, vol. 3d ed., 2010.

About the Author, Dr. Nour Bouhou

Dr. Nour Bouhou, PSP, Vice President at ASLPM is a project management, project controls and construction claims and litigation expert. She began her career as a Field Engineer working her way to serving as a Construction Consultant. In the field, she managed MEP, drywall, and finishes trades on new construction and renovation projects, in both the public and private arenas, on behalf of general contractors and developers. She coordinated safety, quality control and schedule progress via daily walks, subcontractor meetings and field directions.

As a construction and claims & litigation expert, she provides scheduling and change order evaluation services on large scale mixed-used projects, infrastructure projects, as well as military projects requiring DoD cost-loaded schedule reporting and time impact analysis requirement. In claims situations, she performs schedule delay analyses, productivity impact assessments, damages quantifications and serves as a testifying expert.

Dr. Bouhou provides technical trainings to owners and contractors related to scheduling best practices, project controls principles and claims. She published multiple technical and white papers and spoke at about twenty seminars and conferences.

Dr. Bouhou holds a PhD in Civil Engineering from The University of Texas at Austin in the Construction Engineering and Project Management Program.

She is an Adjunct Professor at California State University, East Bay and NKU College of Business, teaching Construction Management and Project Controls courses for the Undergraduate, Master’s and MBA Programs. She also serves as the Regional Director at AACE International and a program chair for the Western Winter Workshop.

![[Free 90-min Masterclass] The Ultimate Leadership Recipe for Project Professionals](https://www.projectcontrolacademy.com/wp-content/uploads/2024/08/4-1024x576.jpg)