AWP is one of the most discussed topics today – specifically on how Advanced Work Packaging benefits projects and industries.

Well, consider the current gloomy state of projects where most do not meet their objectives. It is no wonder that owners and contractors will desperately jump on any advice the industry cooks up.

I received lots of great advice growing up in my teens. A successful family friend once imparted some sage advice to my brother, who then relayed the same to me:

“Think of where you want to be at 50. Then work backward from there, step-by-step.” You could probably read it as ‘plan with the end in mind’ with a bit of nostalgia thrown in.

In the same vein, that is how we realize Advanced Work Packaging benefits, by planning with the end in mind.

But still, is the AWP hype all that it is made up to be?

For that, we invited Chris Carson, Enterprise Director of Program & Project Controls at Arcadis U.S., and one of the instructors of Project Control Academy, for his thoughts. If you are looking for an expert opinion on AWP, look no further than Chris Carson.

Watch the video below to see our very own Shohreh Ghorbani, Technical Director of Project Control Academy interview Chris.

Or, if you would prefer, read our point-by-point summary of the video with some additional content thrown in. The choice is yours, happy learning!

What Is Advanced Work Packaging?

Perhaps you heard through the grapevine that management has decided to implement AWP in their next project. Or maybe YOU have been selected to implement AWP in the organization – as was the fate of one participant in our recent AWP masterclass.

For starters, what is Advanced Work Packaging?

According to the Construction Industry Institute (CII), Advanced Work Packaging is a structured process for planning and execution that aims to align engineering, procurement, and construction.

“Well that sounds fantastic, but we already do something similar in our projects”, you quickly interject.

Indeed, many say that the AWP process is not an entirely new concept in modern construction. They argue that forward-looking organizations have already been performing AWP to some form or degree in their projects.

But look carefully and see if the below still occur despite the processes set up in your organization:

- The design team does not know which Engineering Work Package (EWP) to prioritize first.

- The above manifests itself when long-lead items are not delivered in the sequence required.

- There seems to be an unending list of request-for-information (RFIs) from the execution team.

- The execution team only pays lip service to the so-called “unrealistic” project schedule.

If the above seems familiar, then we recommend you explore below how Advanced Work Packaging benefits your project success rates.

The Process of Realizing Advanced Work Packaging Benefits

The process to realize Advanced Work Packaging benefits was first formally studied by CII – an organization based at The University of Texas at Austin.

Now that came as a pleasant surprise to me. UT Austin is my alma mater and of course a great research university. So that alone really convinced me of the academically rigorous research going into AWP.

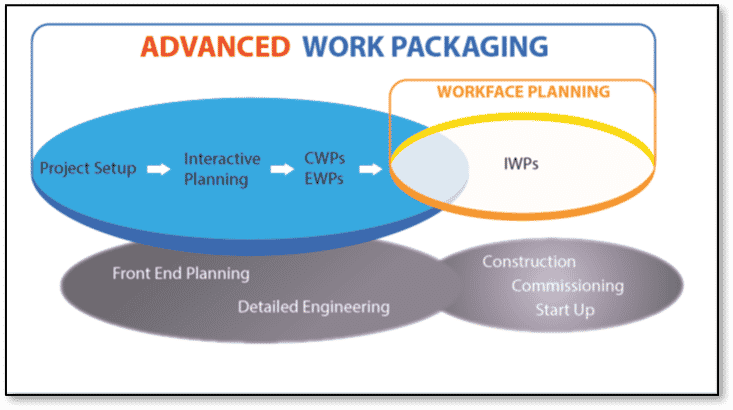

Research into the AWP process identifies three deliverables across the project life cycle. These deliverables provide the framework for execution:

- Construction Work Packages (CWP)

- Engineering Work Packages (EWP)

- Installation Work Packages (IWP)

Figure 1: AWP and the Project Lifecycle from: “Transforming the Industry: Making the Case for AWP as a Standard (Best) Practice,” CII.

In Fig. 1 above, the EWP is the engineering deliverable used to develop the CWP followed by the IWP which guides the workface planning. During the project lifecycle, we typically expect the CWP, EWP, and IWP to be completed in chronological order.

What makes AWP so remarkable is its use of the execution plan as a guideline to align the three deliverables of CWP, EWP, and IWP.

I can almost hear the chorus of silent hurrahs coming from all you CPM-enthusiasts out there.

The Path of Construction To Realize Advanced Work Packaging Benefits

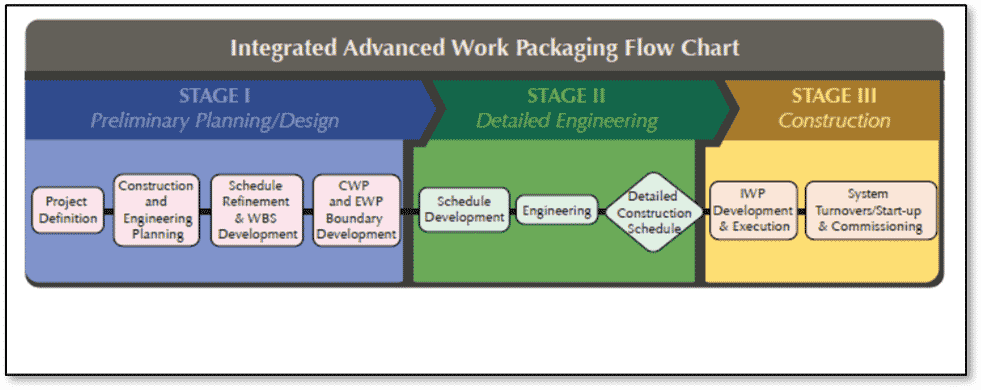

Remember what we said earlier about planning with the end in mind? Hence why AWP advocates using a high-level Path of Construction (POC) even during the early stages of CWP development.

Due to its name, some mistakenly assume that the Path of Construction is developed during workface planning at the Installation Work Package level. As a result, they only focus on clearing issues during execution and become overly optimistic in their AWP implementation.

The truth is, full-on AWP requires the Path of Construction to be used as a guideline at all stages of the project. Specifically, at the Preliminary Planning and Design, Detailed Engineering, and Construction stage such as in Fig. 2 below.

Figure 2: Integrated Enhanced Work Packaging Flowchart from: “Advanced Work Packaging: Design Through Workface Execution,” CII.

Therefore, an organization’s project lifecycle team must collaboratively develop the POC at the early stages or risk failing their AWP implementation.

Oftentimes, that is easier said than done. Not only do you have to get all stakeholders in the same room, but you also need to somehow get everyone to agree on the same thing.

A Common Obstacle To Advanced Work Packaging Benefits

Research shows that employee resistance to change remains one of the major business challenges for many organizations. For example, design teams may argue that project scheduling and engineering design should be independent of each other.

Even as I finish writing the previous sentence I am reminded of my time in a previous consultation.

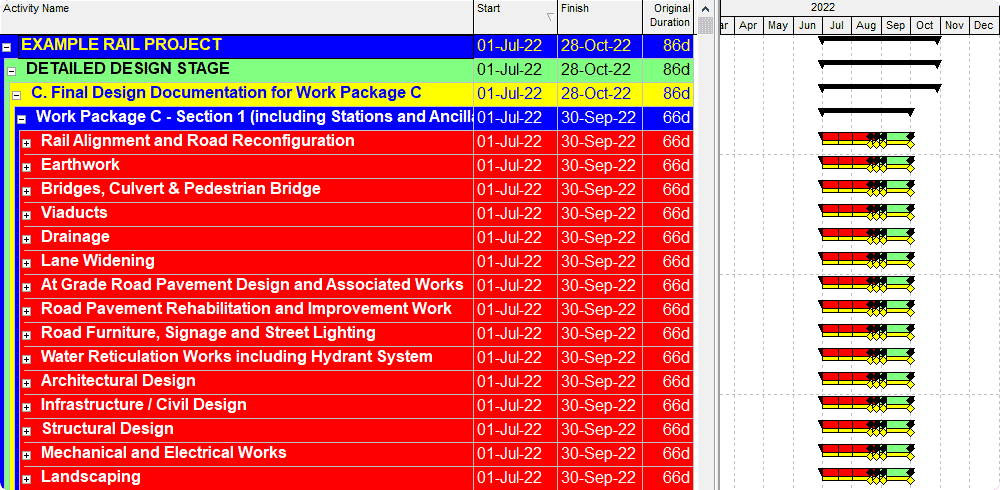

We were assisting a design consultant to convert a tender work program they had developed in Microsoft Project into a Primavera P6 format as per tender requirements. They were hoping to be appointed as the detailed design consultant for a landmark rail project.

As we were performing the conversion, we could not help but notice a glaring error in their project schedule. It was obvious the consultant had not sequenced or prioritized their design packages.

Essentially, they were planning to start and finish all design packages on the same dates! We could almost visualize their design engineers running around like headless chickens during the design stage.

Figure 3: No Clear Prioritization For Design Work Of Different Discipline

We brought our concerns to the design consultant and their replies were nothing short of underwhelming. Oh, it was simply a preliminary program. Yeah, they would work around the resource requirements somehow.

Hence, we recommend being wary yet deliberate in your strategy to implement AWP in projects. Instead of jumping straight into full AWP implementation, aim to guide your organization along a maturity path.

Guiding Your Organization To Achieve Advanced Work Packaging Benefits

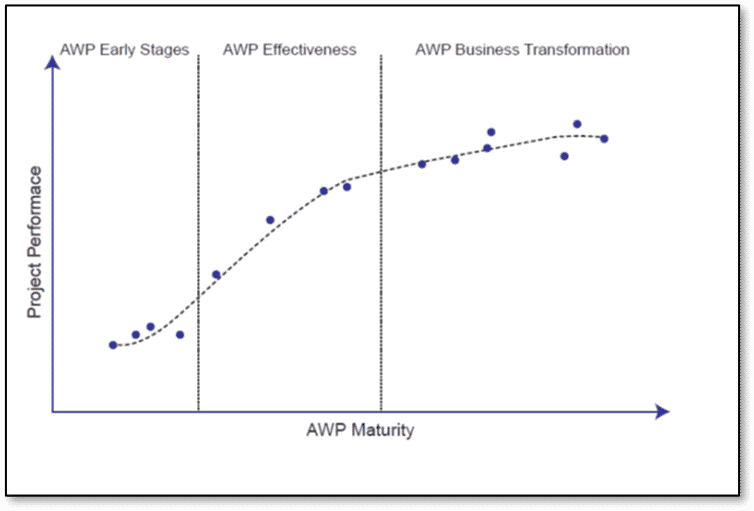

For this, we recommend using the AWP Maturity Model developed by CII to identify a suitable level of AWP implementation.

Use the tool to find a balance between the incremental Advanced Work Packaging benefits you hope to achieve, versus your organization’s readiness to embrace such change.

Figure 4: AWP Maturity Stages from: “Transforming the Industry: Making the Case for AWP as a Standard (Best) Practice,” CII.

Like Fig. 4 above, you aim to increase your organization’s AWP adoption rate to the point of business transformation.

The breadth and depth of the research studies conducted by CII over many projects mean that we can assure our organization’s stakeholders of the benefits AWP will bring at any stage.

As Chris Carson reaffirms, “we get predictability out of it (AWP maturity path) more than anything”.

The results-based research by CII shows that even in the early stages of AWP implementation we can expect an increase in project performance from the baseline.

Exactly what kind of performance improvements are we talking about? Well, read on more below.

Advanced Work Packaging Benefits

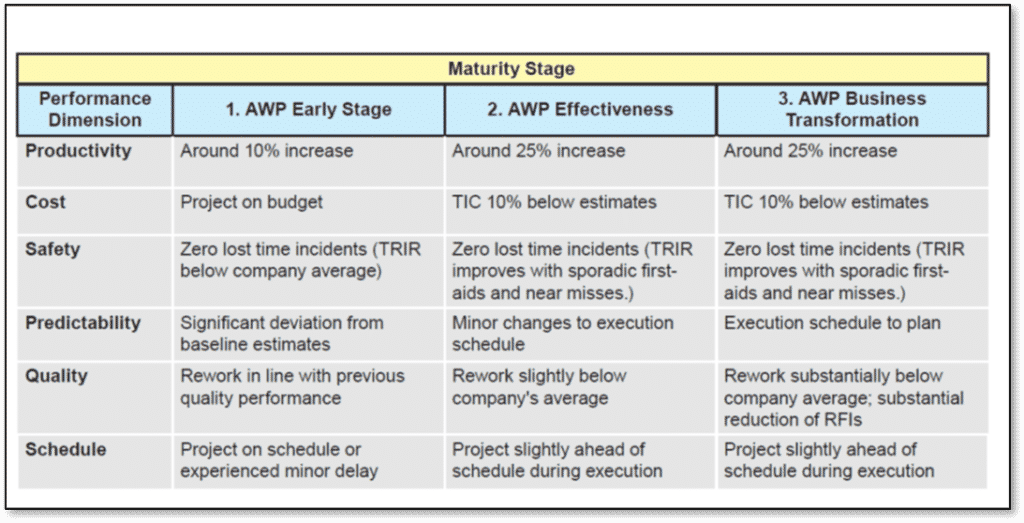

Here are the six Advanced Work Packaging benefits your organization can expect to see at all three stages of AWP implementation:

Advanced Work Packaging Benefits # 1: Enhanced Safety

Safety is paramount above all, that is the mantra drilled into every construction personnel.

I clearly remember my first hitch offshore staying in a work barge. Everyone and I mean everyone had to attend daily safety toolbox meetings at six in the morning without fail. The only exceptions were those from the marine crew or catering team.

To my then-organization, safety culture was not just a checklist but a mindset to adopt.

Throwing back to Fig. 5 below, I can already hear that familiar “dee-dot-dee-dot” warning emitted from the 300MT Huisman crane. Immediately, as if by instinct, everyone on deck would crane (pun intended) their heads skywards to make sure they were clear of the moving crane boom and its load.

Figure 5: Safety Is Paramount Even In The Simplest Operation Such As Routine Lifting

Unfortunately, many organizations do not have the foresight to prioritize safety above other competing elements such as cost and schedule.

So how does AWP help us with our safety visibility? Well, the AWP process requires the project lifecycle team to develop a path of construction early on. Through this, project teams can digitally rehearse the works before it even begins.

They can identify and eliminate working space constraints or detect potentially unsafe working conditions. You do not have to take our word for it, the research speaks for itself.

What happens to the safety record performance of organizations implementing AWP?

For starters, the records show that organizations experience zero lost time incidents at AWP Early Stages. Consequently, the Total Recordable Incident Rate (TRIR) is reduced to below the company average. Then at AWP Effectiveness and AWP Business Transformation, we further see the TRIR improving with only sporadic first aids and near misses.

Advanced Work Packaging Benefits #2: Increased Productivity

There is no doubt safety should rank highest in the minds of every construction personnel. But do you know another construction metric constantly reviewed by project team members, especially the construction manager?

Yes, we are talking about productivity rates.

How much earth are we excavating per week to reach formation-level? How many pipe spool joints are we welding per day?

Many construction teams rely on productivity trend analysis to see if they are on track to finishing on time. In the digital age, project professionals are increasingly turning to Power BI data analytics, transcending clunky spreadsheets. These highly visual dashboards provide insights to justify the project status or to forecast future project performance.

Hence, you will appreciate the fact that even in AWP Early Stages we can expect a 10 percent productivity increase. Even the increased focus on workforce planning is enough to provide a sizable impact to project performance. As we start moving into AWP Effectiveness and Business Transformation, we can expect an impressive 25 percent increase in productivity.

Advanced Work Packaging Benefits #3: Reduced Cost

You may ask next; will we see the same cost benefits as we do for productivity?

Before going into that did you know that only 40 percent of projects are likely to be delivered within budget? Do you think this figure will get any better in the post-pandemic era where material pricing is on the rise? During our Project Control Summit 2021 panel discussion, Mike Brady, Chief Estimator at Bechtel, warned organizations to expect price hyper-escalation.

We need help more than ever to manage our project costs. The sobering statements above are proof of that. The good news is that CII’s research shows that even AWP Early-Stage implementation will help projects complete within budget. Then, as we start moving into AWP Effectiveness and AWP Business Transformation the Total Installed Costs (TIC) start falling 10 percent below estimates.

Are you still with us? We are only just halfway done!

Advanced Work Packaging Benefits #4: Increased Quality

Other Advanced Work Packaging benefits include incremental improvements to the project quality performance.

I was once assigned to a road project where the bridge pile cap was being cast for the first time. One day later, the Contractor was issued a Non-Conformance Report (NCR) for poor workmanship. The NCR alleged that the contractor had performed the concreting work at night and without the supervision of an engineer.

At the next site technical meeting, the contractor hemmed and hawed in their response to the NCR. They claimed that the road access to Pier 2 was in poor condition at the time of casting. Hence, they made an ad-hoc decision to cast Pier 1 pier cap instead and they saw nothing wrong with that.

The client-side project manager was fearless and stood his ground. He forced the contractor to improve their concrete planning and execution.

Finally, the contractor put in their mitigations, the NCR was closed, and the formwork was removed. Sure enough, there was a honeycomb defect and cold joint detected at the casted pile cap.

No prizes for guessing the description of the next NCR given to the contractor.

Figure 6: Example Of Honeycomb Effect – A Concrete Structure Defect That Is Anything But Sweet

The first question that comes to mind is how could the contractor not have anticipated the poor site conditions? How can project teams avoid similar situations?

The AWP process guides the construction team to go through the process of early planning. The construction team can detect possible bottlenecks and remove them quickly, leading to less rework.

At the AWP Business Transformation stage expect to see the rework rate reduced substantially to below your organization’s average. Likewise, expect a similar reduction in Request for Information (RFIs) as scope uncertainty is progressively eliminated during the design stage.

Advanced Work Packaging Benefits #5: Project On Schedule

The benefits of completing a project on time should need no introduction. But many project team members still do not take schedule delays seriously.

My go-to solution is to take out my trusty Casio calculator. I then ask for the project Liquidated Ascertained Damages (LAD) amount. LAD is a contractually agreed sum of money that the contractor agrees to pay to the client for every day the project is delayed.

I then proceed to multiply the current quantum of project delay by the LAD amount and read out the figure. This, I tell the Project Manager, is the amount your organization can expect to fork out at project completion. Usually, this gets their attention to start participating in delay mitigation discussions.

The AWP process is CPM-centric so even AWP Early Stage can help projects complete on time or with only minor delays. As we move further into AWP Effectiveness and AWP Business Transformation, expect projects to even complete slightly ahead of schedule.

Advanced Work Packaging Benefits #6: Project Predictability

Finally, with all the Advanced Work Packaging benefits to safety, productivity, cost, quality, and schedule as summarized in Fig. 7 below, we start developing a sense of predictability to the project.

Figure 7: AWP Maturity Stages and Project Performance from: “Transforming the Industry: Making the Case for AWP as a Standard (Best) Practice,” CII.

We will still see significant variation from baseline estimates during the AWP Early Stage. However, as we start moving into AWP Effectiveness, expect only minor changes to the execution schedule. As we reach AWP Business Transformation, executing according to the plan becomes the norm and not the outlier. With all project management constraints in perfect harmony, we no longer expect ‘change to be the only constant’.

Summarizing Advanced Work Packaging Benefits

If you were asked to define AWP in a few words, let it be “planning with the end in mind”.

Essentially, we are taking a page out of something we already do very well, which is installation-level planning. Then we work backward to reap the benefits of that planning starting from the earliest project lifecycle.

Specifically, organizations stand to benefit from enhanced work safety levels while experiencing a boost in productivity. Construction rework is significantly reduced and as a result, Total Installed Costs are reduced to 10 percent below average. Furthermore, there is a high possibility to complete the project on time.

With all the predictability gained by the well-performing metrics above, project teams can finally execute according to the plan.

So are you sold on AWP yet?

With AWP, reaching your project objectives is no longer a pipe dream! If you are ready to get started on your AWP journey, then you need to read our next article. Follow us and find out how you can begin implementing AWP, step-by-step in your organization.

References:

[1] “AIPM and KPMG Project Management Survey 2020.” home.kpmg, KPMG,

[ 2] Ghorbani, Shohreh. “Understanding Critical Path Method (CPM)“. Project Control Academy, 9 Oct 2014.

[3] Lawrence, Paul R. “How to Deal With Resistance to Change.” Harvard Business Review, Jan 1969.

[4] Pilcher, Chris. “The Beginning of a 4D Journey“. Project Control Academy, 19 Jun 2016.

[5] Jacob, Joel. “An Introduction to Visual Data Analytics with Power BI“. Project Control Academy, 24 Jul 2021.

[6] 2021 Project Control Summit. “Cost Management Best Practices & Lessons Learned”. Project Control Academy. Moderator: Lance Stephenson. Panelists: Nicole Carberry, Mike Brady, Joshua Rowan.

[7] Ochiche, Simeon. “Understanding and Balancing Project Constraints, a Key to Project Success“. Project Control Academy, 8 Aug 2016.

[8] Carson, Chris. “How You Can Efficiently Evolve From Project Scheduling To Implementing Advanced Work Packaging (AWP) With Ease”. Project Control Academy, 26 Mar 2021.

About the Author:

Bian comes from a conventional Planning & Scheduling background and is also a trainer with technical capabilities in 4D BIM Planning and Advanced Drone Photogrammetry. He is currently consulting for several key infrastructure projects such as the Pan Borneo Highway project in Sarawak under PCSS Consultancy Sdn Bhd and has worked in the oil & gas industry developing maintenance schedules for a major oil and gas operator.

He holds a Bachelor of Science (BSc.) in Petroleum Engineering from The University of Texas at Austin. Bian was an invited speaker for The Institution of Engineering and Technology (IET) Evening Talk 2020.

![[Free 90-min Masterclass] The Ultimate Leadership Recipe for Project Professionals](https://www.projectcontrolacademy.com/wp-content/uploads/2024/08/4-1024x576.jpg)