Is Advanced Work Packaging (AWP) truly the right path for your organization?

It’s perfectly normal to have lingering doubts as you only want the best for your organization. Indeed, full AWP implementation requires a significant amount of time and resources.

But organizations don’t have to implement full AWP head-on. You can implement AWP in stages following the AWP Maturity Path. The AWP Maturity Model makes it easy to predict the positive impacts you can achieve with each incremental effort.

But perhaps your question is whether you should even begin at all? This is why we are writing this article today, to help you make that final decision.

For that, we have Chris Carson, a thought leader in Project Controls and one of the instructors of Project Control Academy, to help you make that decision.

So let’s watch the video below to see if Chris can’t help you make this important decision.

Or, if you would prefer, read our point-by-point summary of the video with some additional content thrown in. The choice is yours, happy learning!

3 Questions To Ask Yourself Before Implementing Advanced Work Packaging (AWP)

We have compiled a list of questions below for you to review. We think these questions should rank high up on the list of a decision-maker such as yourself. You can assess the suitability of Advanced Work Packaging (AWP)’s for your organization by asking these three questions below:

1. Is Advanced Work Packaging (AWP) Suitable For My Project Delivery Method?

This is a common question asked by both Owners and Contractors alike. Both parties want to know what’s in it for them and whether AWP is worth it.

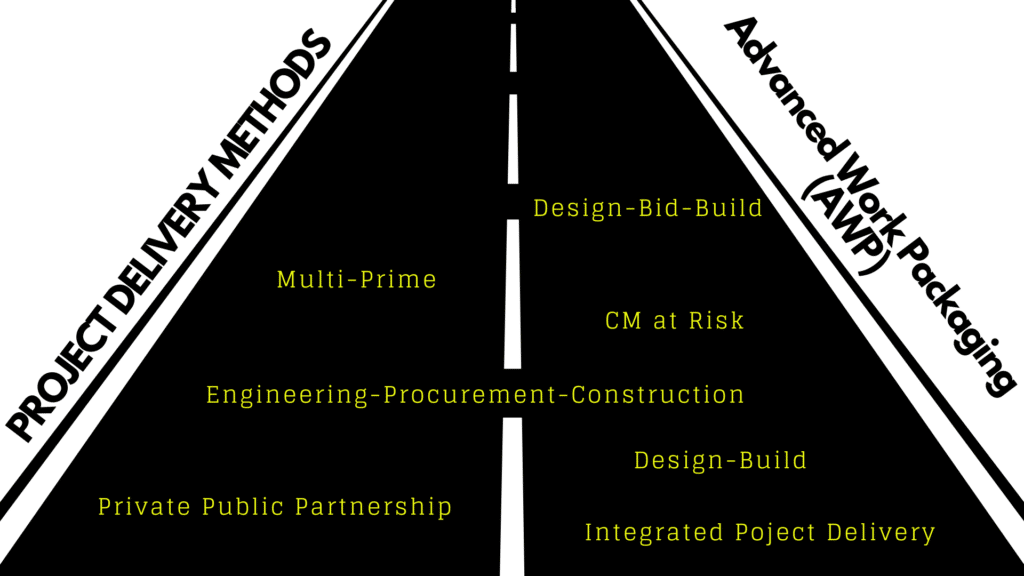

Before we go there, let’s refresh our memory on some of the most common project delivery methods:

- DBB – Design-Bid-Build

- EPC – Engineering-Procurement-Construction

- DB – Design-Build

- P3 – Private Public Partnership

- CMAR – Construction Management at Risk

- IPD – Integrated Project Delivery

- Multi-Prime

Figure 1: Project Delivery Methods That Work With Advanced Work Packaging (AWP)

So the question is, which of the above is most compatible with Advanced Work Packaging (AWP)?

The short answer…

All of them! They just require different approaches.

That is largely due to AWP’semphasis on team collaboration, communication, and good CPM scheduling, which works well across any project delivery method.

Let’s take the EPC project delivery method as an example.

EPC is a common project delivery method in the oil and gas (O&G) industry. Its typical high-stakes environment means that planning and scheduling techniques tend to be more process-driven. Hence, it comes as no surprise that O&Gindustry players were among the first to adopt AWP philosophies. This industry saw the value of using AWP to sequence engineering packages of manageable size. Design mistakes can be very costly to the overall project success. For example, in the case of the installation of offshore topside structures.

Whereas for the Design-Build project delivery method, critics often point out the limited usefulness of AWP.

They state that the work is handed off to the contractor at 30 percent documents. But remember that work packages still need to be developed, either on the owner side or the designer side. Hence, work package development still stands to benefit from the strong sequencing emphasized in the AWP process.

And if you’re in Integrated Project Delivery (IPD)? Then you’re a lucky project manager because IPD requires a team to be put together at the early stage. And that is exactly what the AWP philosophy is about: having an early, collaborative project lifecycle team at the onset.

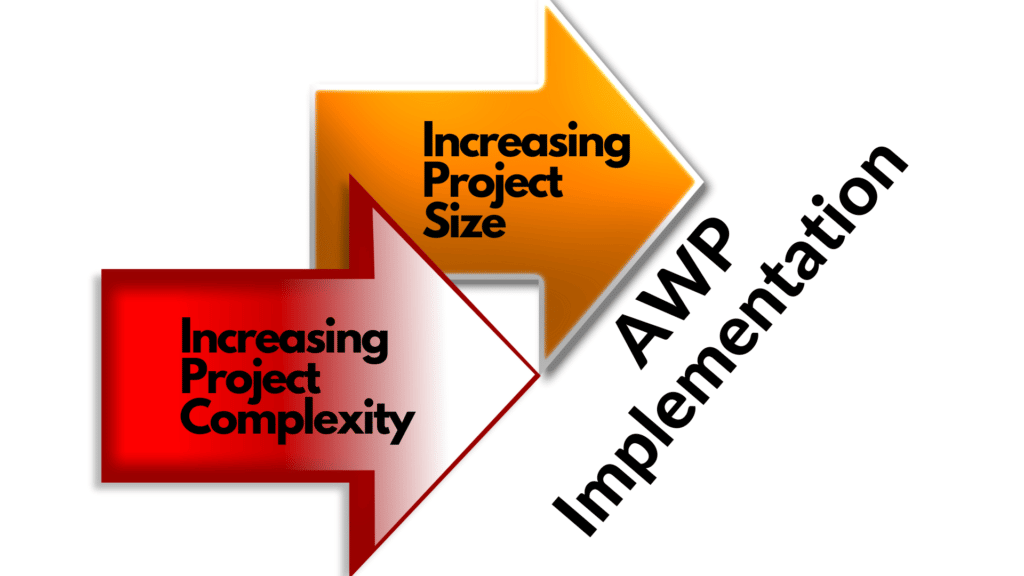

2. Is My Project Big Enough To Implement Advanced Work Packaging (AWP)?

So we now know that AWP benefits any type of project regardless of its delivery method, albeit with varying degrees of compatibility.

But what if it isn’t just a question of type of project’ but ‘size of the project’?

Specifically, is there a minimum value or duration of a project that justifies its adoption of AWP? Or perhaps, is there a degree of complexity in a project that rationalizes the use of AWP?

Figure 2: Is AWP Implementation Only Justified With Increasing Project Size and Complexity?

These are all valid questions that we will address specifically in our next AWP blog post series.

But for now, let’s take a step back and look at the bigger picture.

Advanced Work Packaging (AWP) isn’t your typical initiative that can be tested and validated at a pilot project level. AWP’s emphasis on early planning and collaboration dictates that the implementation must start at the organization level. Otherwise, you risk failing your project-level AWP implementation altogether.

Hence, the question to be asked isn’t whether your project is big enough for AWP, but whether your organization is willing to handle AWP. And that feeds a lot into your organization’s growth and sustainability vision.

In my region, tenders from the Oil &Gas industry have already started mandating the use of AWP philosophies. I had a taste of that already and I shared my experience in our AWP implementation guide.

Extrapolating ahead, it’s only a matter of time before other industries follow suit.Hence, it makes sense for organizations to get their hands dirty on AWP now so that they remain competitive years from now.

So will your organization be left behind? Or will you attempt to explore AWP and reap its benefits?

3. Will Advanced Work Packaging (AWP) Disrupt My Existing Company Processes?

Okay, so we have convinced you to implement Advanced Work Packaging (AWP) at your organization level. But you might worry if implementing AWP will forcefully overhaul existing company processes.

We understand where you’re coming from.

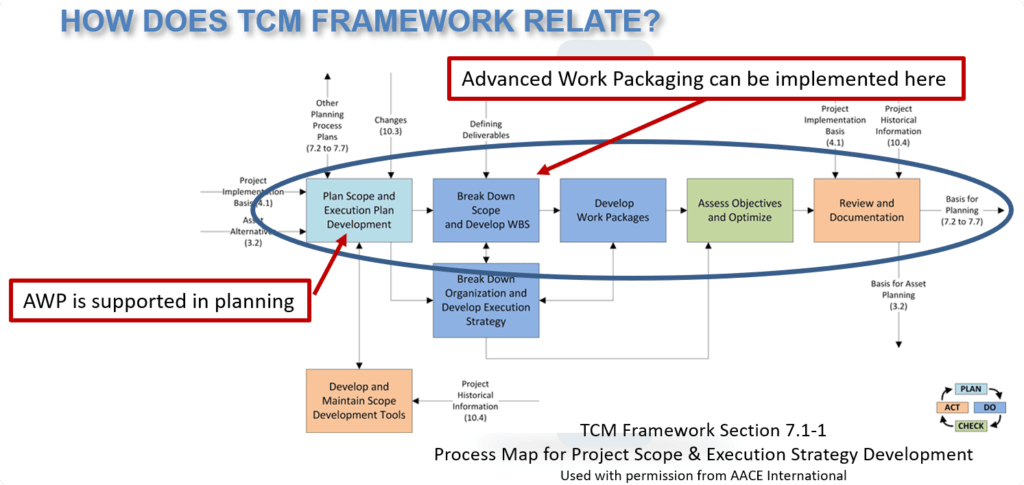

Take for example the Total Cost Management (TCM) Framework by the Association for the Advancement of Cost Engineering (AACE). Many organizations have built their cost management processes around the reliable TCM framework.

Similarly, your organization may have spent great effort integrating the TCM framework within the company structures. So do you have to throw it all away for the new kid in town?

Short answer? No, you don’t. And we have Chris Carson to thank for his research.

Already recognized as the Top 10 Contributor to AACE’s Recommended Practices, Chris conducted his due diligence in assessing AWP-TCMcompatibility.

Let’s see Chris’s recommendations on where AWP can fit within the TCM Framework in Fig.3 below:

Figure 3: TCM Framework Section 7.1-1 Showing Where AWP Can Be Accommodated

We start with TCM Section 4.1, which discusses the Project Implementation, asset scope, objectives, and assumptions.

Remember that Advanced Work Packaging (AWP) also emphasizes similar collaborative discussions between project lifecycle teams.

Moving on to TCM Section 7.1.1 we then start to Plan the Project Scope and Execution Strategy using a stage-gate process. This is parallel to AWP’s Path of Construction (POC) discussions where project lifecycle teams must develop an early, detailed plan.

Next in TCM Section 7.1.2, we start to Break down the scope and Develop the Work Breakdown Structure (WBS). Similarly, in the AWP process, we must break down the ultimate deliverable to several Construction Work Areas (CWA).

Finally, in TCM Section 7.1.4 we Develop Work Packages which are the integration of Organizational Breakdown Structure (OBS) and WBS. Hence, this section defines the scope and responsibility of each party. In the AWP process, we capture similar information in Construction Work Packages (CWP).

So, summarizing below:

TCM does not explicitly show Advanced Work Packaging (AWP):

- Section 7.1 of TCM tends to emphasize iterative processes rather than sequencing.

- Sequencing tends to be part of the planning discussion into execution strategies.

However, TCM can easily accommodate Advanced Work Packaging (AWP):

- Section 4.1 of TCM helps establish the goals for sequenced work packages.

- Section 7.1.1 of TCM helps establish the need for sequenced work packages.

- Section 7.1.2 of TCM helps establish the plan for sequenced work packages.

- Section 7.1.4 of TCM helps define scope and responsibility for sequenced work packages.

Advanced Work Packaging (AWP) – In Summary

So let’s summarize again why Advanced Wok Packaging (AWP) is truly the right path for your organization.

For starters, AWP works for all project delivery methods thanks to the strong emphasis on collaboration and good CPM scheduling. This provides a win-win situation that benefits both owners and contractors alike.

On the outside, it may seem worthwhile to only implement AWP on large, complex projects. But effective AWP implementation often requires commitment at the organization level. So questioning the project size is somewhat irrelevant. Visionary organizations, regardless of their size, view AWP as a tool to maintain their competitive edge in years to come.

And the best part?

You don’t need a major overhaul to your organization’s best practices for it to adopt Advanced Work Packaging (AWP). AWP has already so much in common with industry best practices such as the Total Cost Management (TCM) framework.

So if you were previously on the fence with regards to Advanced Work Packaging (AWP), we hope this blog post has given you a clear answer.

But it doesn’t hurt to be careful! We understand if you still have some off-the-beaten-path questions about Advanced Work Packaging (AWP).

This is why you need to read our next blog post which we have specially prepared for you. Watch us answer the most frequently asked questions (FAQs) regarding AWP in the next blog.

So see you there!

References:

[1] Mutang Tagal, Bian. “The Top 6 Advanced Work Packaging Benefits That You May Not Have Heard About“. Project Control Academy, 08 Mar 2022.

[2] Mutang Tagal, Bian. “The Ultimate Checklist for Effective AWP Implementation In Your Organization“. Project Control Academy, 22 Mar 2022.

[3] Mutang Tagal, Bian. “The Top 4 Costly Mistakes To Avoid During AWP Transition”. Project Control Academy, 5 Apr 2022.

[4] Carson, Chris. “How You Can Efficiently Evolve From Project Scheduling To Implementing Advanced Work Packaging (AWP) With Ease”. Project Control Academy, 26 Mar 2021.

[5] Stephenson, Lance. “Total Cost Management Framework”, 2nd Edition, AACE®, 2015.

[6] Ghorbani, Shohreh. “Project Controller vs. Good Communicator“. Project Control Academy, 21 Sep 2013.

About the Author:

Bian comes from a conventional Planning & Scheduling background and is also a trainer with technical capabilities in 4D BIM Planning and Advanced Drone Photogrammetry. He is currently consulting for several key infrastructure projects such as the Pan Borneo Highway project in Sarawak under PCSS Consultancy Sdn Bhd and has worked in the oil & gas industry developing maintenance schedules for a major oil and gas operator.

He holds a Bachelor of Science (BSc.) in Petroleum Engineering from The University of Texas at Austin. Bian was an invited speaker for The Institution of Engineering and Technology (IET) Evening Talk 2020.

![[Free 90-min Masterclass] The Ultimate Leadership Recipe for Project Professionals](https://www.projectcontrolacademy.com/wp-content/uploads/2024/08/4-1024x576.jpg)